Addressing Dioxin and Furan Contamination

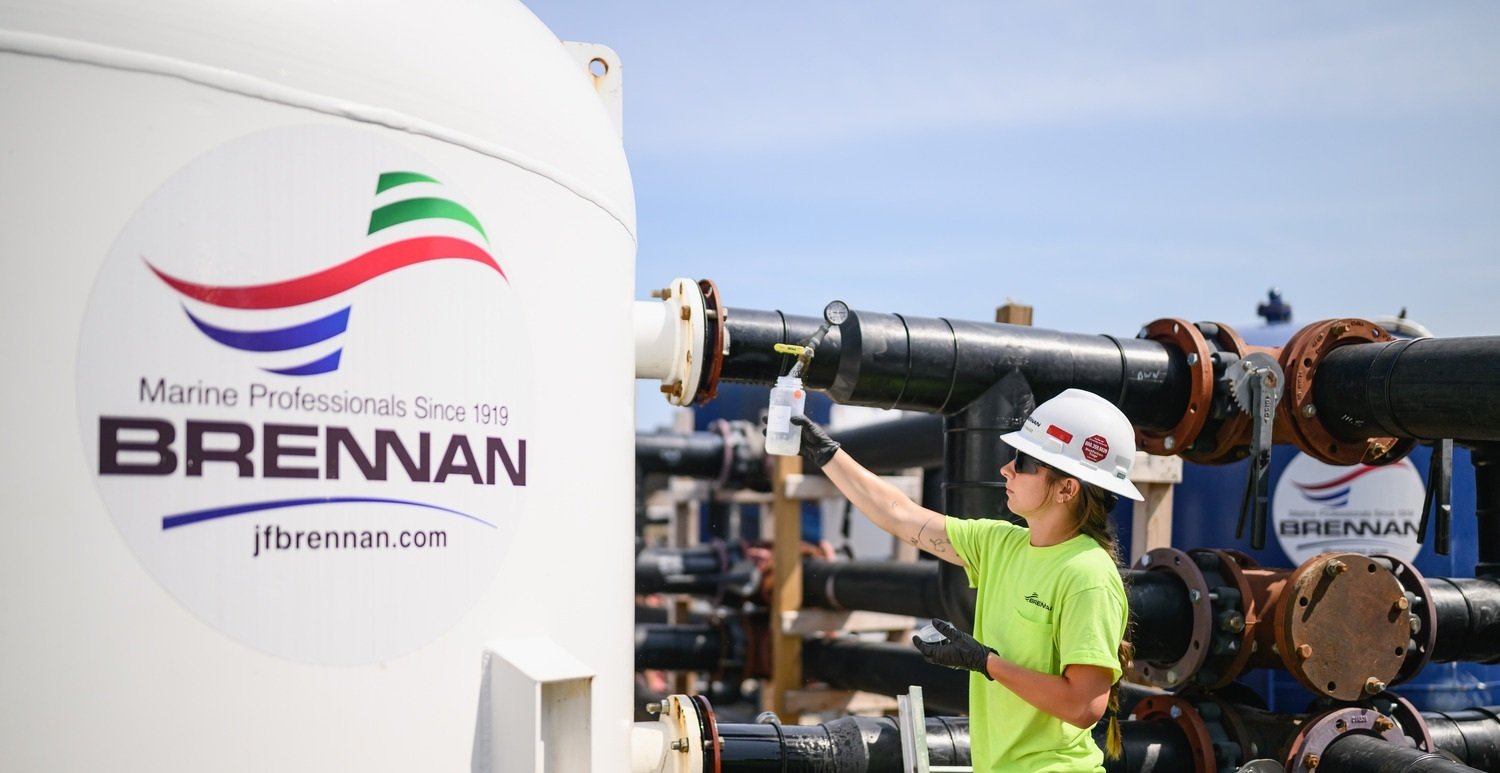

Under the Great Lakes Legacy Act, and in partnership with the Minnesota Pollution Control Agency (MPCA) and an industry partner, the US Environmental Protection Agency’s (EPA) Great Lakes National Program Office requested construction services to address dioxin and furan contamination within Thomson Reservoir. The project, located in Carlton, Minnesota, was awarded to Brennan in the spring of 2024.

Our contract included placing a thin layer of amendment containing 10% powdered activated carbon (PAC) across the reservoir to address approximately 225,000 cubic yards of contaminated sediment. This remedy represents the largest remediation project of its kind implemented in the United States to date and is designed to reduce the bioavailability of toxins in surface sediments to macroinvertebrates, an essential food source for fish.

.jpeg)