Lock and dam and hydropower infrastructure face numerous unique challenges when it comes to improving the safety and reliability of existing dams. An important structural enhancement for dam stabilization projects is the installation of high-capacity post-tensioned anchors, which may supplement or replace existing anchors.

According to the Post-Tensioning Institute, post-tensioned rock and soil anchors provide a cost-efficient, high-performance solution for projects needing both temporary and permanent stabilization solutions.

Post-tensioning is a technique for reinforcing concrete with high-strength steel strands or bars, also known as tendons. There are numerous different post-tensioning applications in the construction industry, and one of those is dam stabilization.

What Are Post-Tensioned Anchors?

Post-tensioned anchors are a relatively cost-effective way to address dam safety concerns. They are used in various applications, from aging concrete structures and compromised construction joints to reinforcing additional storage capacity and planning for future flood levels. Post-tension anchors can extend the lifespan of a dam by reestablishing its structural integrity and improving its stability.

Post-tensioned anchors are a relatively cost-effective way to address dam safety concerns. They are used in various applications, from aging concrete structures and compromised construction joints to reinforcing additional storage capacity and planning for future flood levels. Post-tension anchors can extend the lifespan of a dam by reestablishing its structural integrity and improving its stability.

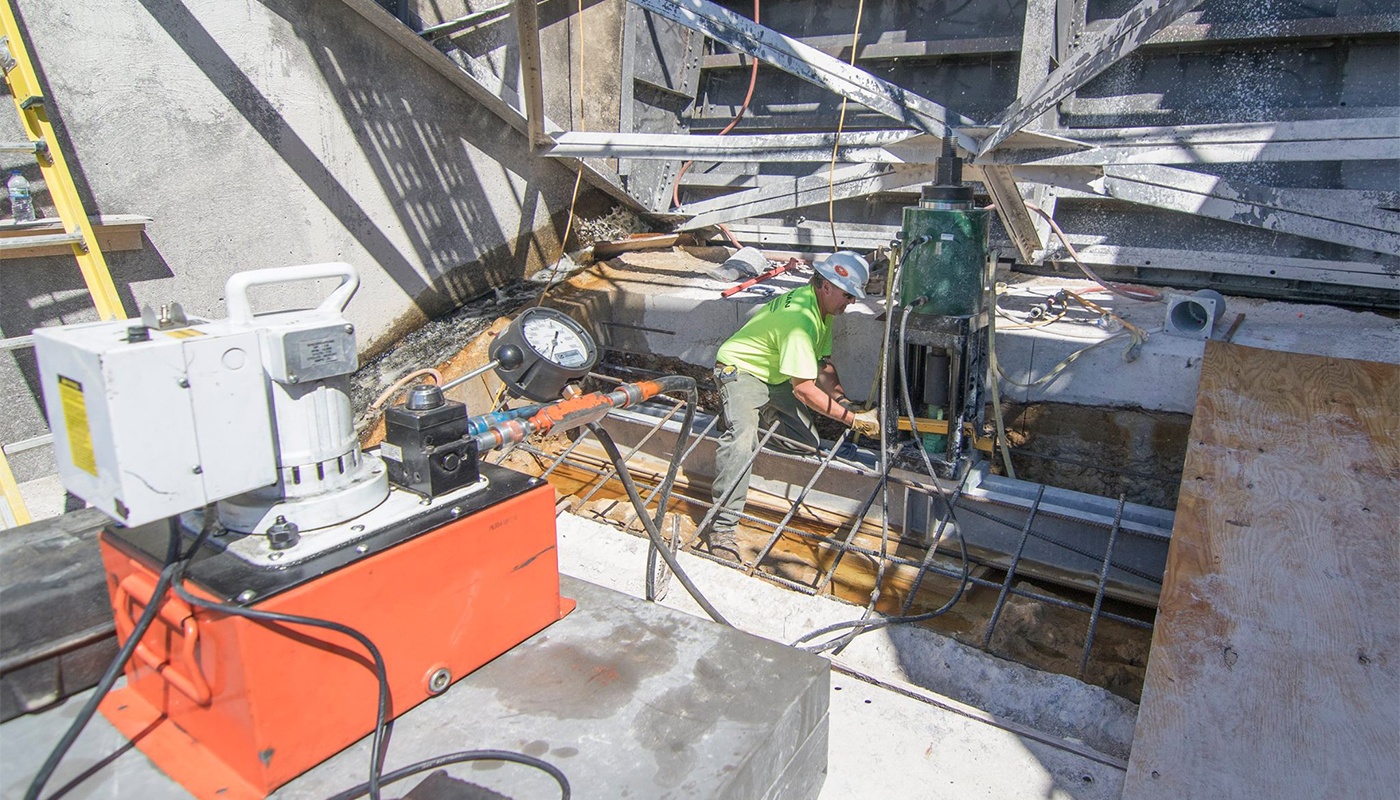

There are numerous aspects to consider when designing and constructing a post-tensioned anchor project. Costs, work area, equipment, and material needs are important factors. Extremely technical work, like anchor drilling and hydro demolition, requires specialized training and should also be considered.

Another important design consideration is which drilling method to utilize when creating the anchor holes, with the two most popular methods being core drilling and rock drilling.

Enhancing Dam Safety - Cable vs. Bar Anchors

When considering the design and constructability of anchor installation, it is important to determine whether to utilize cable strand anchors, bar anchors, or a combination of both.

When considering the design and constructability of anchor installation, it is important to determine whether to utilize cable strand anchors, bar anchors, or a combination of both.

The deeper the anchor goes, the more cost-effective cable stand anchors become, as it is possible to fabricate these strands in a continuous length. Deeper bar anchors require the use of couplers due to manufacturing limitations.

Bar anchors are more rigid than cable strand anchors and are not as easy to work with, employing a different grouting sequence. Modern bar anchors can come fabricated with bond breaker materials that allow for easy one-step grouting from bottom to top in one shot rather than a primary and then secondary grouting process.

Pros and Cons of Different Drilling Methods for Anchor Holes

The 2 most frequently used methods for drilling anchor holes are core drilling and rock drilling - each has pros and cons.

Core Drilling

Core drilling is very portable due to the smaller equipment size, which makes it easier to work in tight access or remote places. Core drilling can also tell an engineer much about the structure since you can analyze the core upon removal.

Core drilling is very portable due to the smaller equipment size, which makes it easier to work in tight access or remote places. Core drilling can also tell an engineer much about the structure since you can analyze the core upon removal.

However, core drilling is a slower operation, which can drive up labor costs. Core drilling is also susceptible to issues during the drilling process, including the drill getting stuck.

Granular bedrock, such as sandstone, can also cause problems for core drilling. As a core drill progresses, water is flushed down the inside of the coring bit. This water brings the “cuttings” up and out of the hole along the outside of the drilled core, a relatively small annulus space. This is generally not a problem when drilling through concrete or hard bedrock since the “cuttings” are a liquid slurry.

In the case of sandstone, the slurry contains granular particles that can become lodged in the annulus space and seize up the drill. There are ways to combat this, but it either involves more time to drill slower or incorporate bentonite in the slurry, which is not always desirable.

Rock Drilling

Rock drilling, on the other hand, is a faster method for drilling. This drilling method pulverizes the concrete and bedrock removed from the hole via air pressure. Modern accessories to rock drills incorporate a misting system to provide dust control, which helps meet new silica standards set by the Occupational Safety and Health Administration (OSHA).

Because the rock drills pulverize the rock, they are typically not susceptible to the challenges of drilling deep holes or in the granular substrate. A downside of this method is that it prohibits examination of the structure as a core drill would (although cameras can be used to examine construction joints). Depending on design considerations regarding hole size and drill depth, rock drills are often less portable than core drills.

No matter which of these two drilling methods occurs, each is fully capable of drilling through embedded steel rebar that might appear, and both can adjust to achieve angled core holes as required by design.

A Stable Future with Post-Tensioned Anchors and Dams

When considering the execution of a dam stabilization project, the size, number, and makeup of the anchor system is largely a design decision, but constructability must be a factor.

It is an excellent idea to consult with a specialized contractor familiar with post-tension anchor installation beforehand to ensure that the appropriate anchor makeup (cable or bar) and drilling method (core or rock) are employed, as choosing the right material and technique for the job is a vital component to ensuring success.

For more information on constructability reviews and the benefits of early contractor involvement, read more on our blog: https://www.jfbrennan.com/blog/contractors-constructability-review

This article was originally published by J.F. Brennan Company in 2018.