At Brennan, we work on dams of various sizes and functions. Very few new dams are built each year, so most of our work consists of rehabilitation and repairs. Dams are built to last for long periods of time, however certain components require periodic repairs and replacements. Radial gates, often referred to as Tainter gates, consist of components most commonly in need of attention. In our experience, we have found certain best practices that will increase the longevity of these gates, as well as increase their functionality.

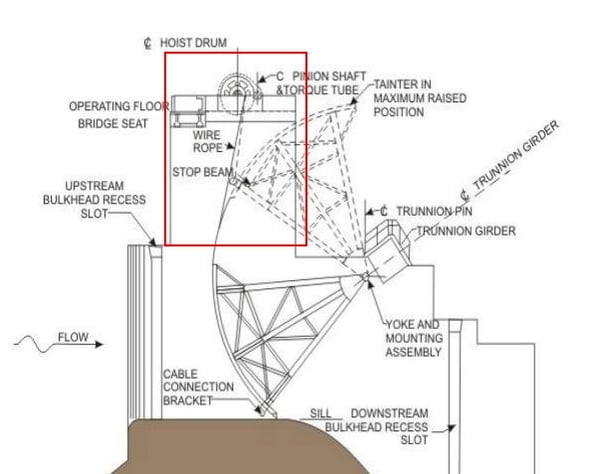

Typically, a tainter gate has two pick points, one on each side, that are used to open and close the gate to control water flow through the dam. The hoist lines, steel cables, or chains are attached to each pick point, and an actuator (such as a hoist) is used to raise the gate. The gate pivots around a trunnion on each side and water can then pass underneath.

Tainter gates are often large, and if the hoist is off center, or the lines are not tensioned properly they will distort as they are raised. This causes unnecessary wear and tear on side seals, damage to the concrete walls in the bay, and eventually the gate itself will have permanent deformation. Tensioning the steel cables or chains is not difficult and will increase the lifespan and functionality of the gate. This extra step can save a lot of money in the long run!

How to Test Tension on Tainter Gates

Many of the tainter gates we have rehabbed and replaced over the years were tensioned using eyesight or ‘sense of feel’ by the contractor or owner’s maintenance personnel. If it looked level, then both sides must have the same tension, and that was good enough. If each hoist line ‘felt’ as tight as the other, then that was good enough. This can be deceiving because eyesight and feel are not the best tools to measure tension. Eventually damage will be found somewhere in the overall gate system (gate itself, seals, concrete, rub plates, etc.) as time goes on.

Additionally, over time, a properly tensioned gate can get out of adjustment as well. This can happen for a number of reasons such as wear and tear of components, gate/hoist misalignment, or stretching of the hoist lines to name a few.

As a rule, the tension on each line needs to be within five percent of each other when there is only one steel cable or chain attached to the pick point. On larger dam gates where there may be two or more tension lines on each side of the gate, each cable should be within two percent, as a rule of thumb, of the ones in that group, and side to side comparisons need to be within five percent. If your tension is off too much on one side, the gate will begin to distort when it is picked.

There are multiple tools available for testing tension, the three we typically use are:

- Strain gauges

- Tension meters

- Come-along ratchets

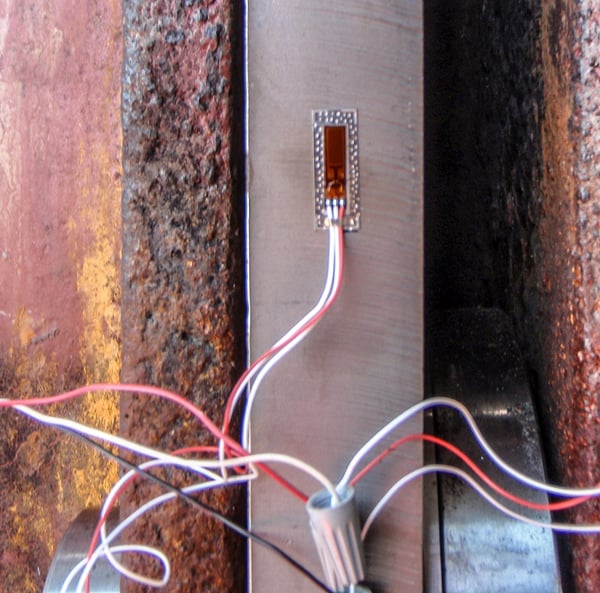

Strain Gauges

A strain gauge works by converting the tension, or force, present in the lines into a change in electrical resistance, which can subsequently be measured. This method works for both chains and cables, as long as there is a place on which to weld the strain gauges.

As the gate is lifted and the cables or chains are put into tension, the strain gauge is also put in tension. The electrical resistance will vary depending on the amount of tension detected. The goal is to adjust it so that the measured tension on each hoist line falls within the percentages mentioned above. Strain gauges can be the most expensive option, but they are also the most accurate.

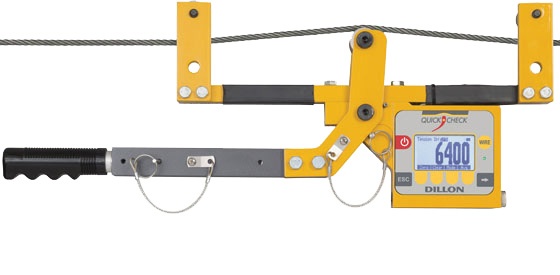

Tension Meters

Tension meters only work if the gate hoists are cables, they will not work on chains. The meter is a handheld device that attaches to the cable and a load cell measures the tension. A tension meter is a quick way to get an accurate reading without a lengthy set-up process that includes welding.

Come-along Ratchets for Quick Tensioning

Some of our clients do not require highly accurate tensioning. They want a quick (somewhat accurate) way to achieve equal tension, but without the use of strain gauges or meters. Plus, come-along ratchets can be used on any type of hoist line, chains or cables. We simply use a come-along, a hand-winch with a ratchet. Despite lacking some of the precision of other methods, the come-along method is still more accurate than the visual or feel techniques, and will still exponentially increase the longevity of your gate system.

The come-along attaches to the gate hoist lines on each side of the gate. As the come-along is ratcheted down, it will apply an equal amount of force perpendicular to the line of action. You then take various measurements to determine if one hoist line is less tensioned that the other. If it is, then the tension needs to be adjusted on that side. Ideally, the measurements should be equal when they are balanced in tension.

Unlike the strain gauges and tension meters, the come-along will not give you a converted measurement of the tension nor can an exact percentage be determined. That being said, the accuracy can be surprisingly higher than you might think. This is the reason that using a come-along is typically the least expensive of the tension testing methods and is often used. It also allows for periodic checks as a means of preventative maintenance.

Adjusting Gate Tension

It is important to have the means to adjust the tension of the hoisting lines built into the system, whether it be at the connection point where the line attaches to the gate or in the machinery. Means to adjust the tension in the chains include a turnbuckle, link bar, connection points, or in the hoist itself.

Adjusting the tension is not as straightforward as one may think. Different line-types and adjusters have different challenges. For instance, if the line is a cable, then it can stretch more so than a chain. Another challenge is whether the bay needs to be dewatered or perhaps the gate needs to be supported in some manner to make an adjustment.

Chains on the other hand, are rarely the same length. When a manufacturer makes a chain, each link has a tolerance. When the links are put together, the tolerances can add up causing length variations. For instance, two 20-foot chains are unlikely to be the same length because of the cumulative tolerances in the links. Keep in mind that chains can stretch as well not to mention change in length as the wear. It is no different than the cables on your bicycles’ brakes or the chain on a chainsaw stretching.

Monitoring Your Gate Tension

Tension is a facet to keep an eye on in the future, and it is a good idea to ensure you do routine checks on your gate hoist lines. Anytime you disconnect and reconnect gate hoists lines you should check their tension. Periodic checks are also recommended because components can stretch or wear, and the gates can warp. This can lead to damage on the side seals, adjacent concrete in the gate bays, or other components like the trunnion pins, bushing, and hubs.

Conclusion

Tensioning tainter gate hoist lines properly can be an overlooked step in the process, but it is critical to maximizing the lifespan of a gate. Ensuring that your hoist lines stay appropriately tensioned is a proven process in preventing unnecessary damage to your structure and will increase the longevity of your gate.

Click here to visit our dam construction page for more information on gate and actuator installation.